How to Operate the Shoe Soles Flexing Tester ULB-FD01

How to Operate the Shoe Soles Flexing Tester ULB-FD01

I. Overview

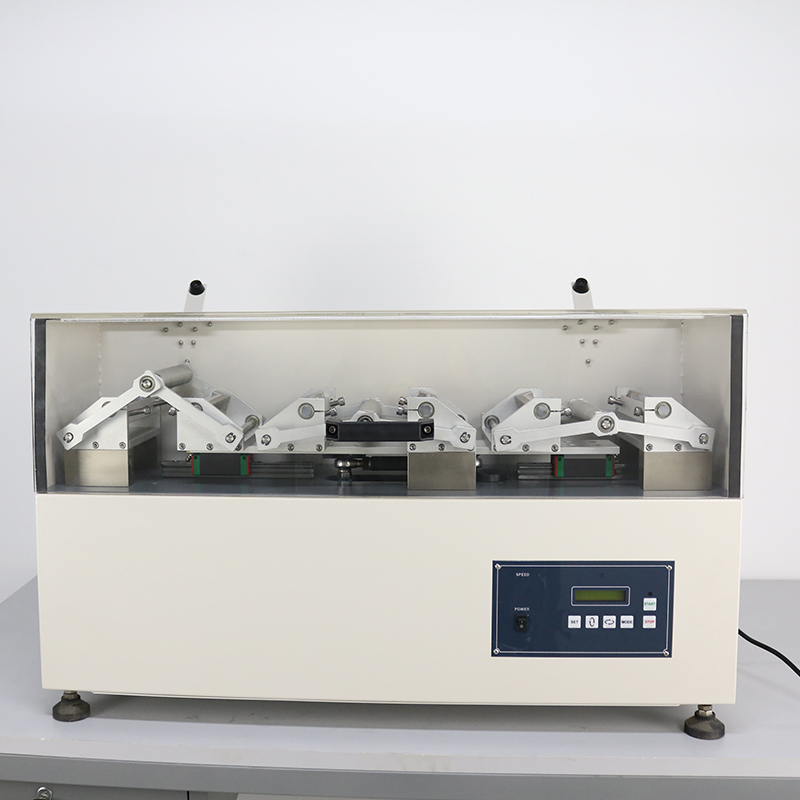

The EN Sole Flexing Tester serves as a professional tool for evaluating the flexibility of shoe soles. It mimics bending conditions during usage to assess durability and quality accurately. Precise execution of its operational procedures is essential to obtain reliable test results. This guide will elucidate the steps for operating the sole flexing tester, enabling users to conduct tests with precision and efficiency.

II. Preparations

Thorough preparation is imperative to ensure seamless testing procedures.

When inspecting equipment, commence by scrutinizing the external appearance of the Shoe Sole Flexing Tester to detect any damages or anomalies such as cracks, deformations, or loose components. Next, meticulously examine the power cord and plug to ensure they remain undamaged and firmly connected. Verify the proper functioning of the power switch to facilitate smooth startup and shutdown of the device. Finally, perform simple functionality tests, such as initiating the device and verifying the correct operation of the status indicator lights and various functions through the control panel.

III. Operational Procedures

1. Connect to the 220V 50/60 Hz AC power supply.

2. Power on the device and turn the rotary knob clockwise to activate the emergency power switch.

3. Access the language selection interface and navigate to the English page.

4. Utilize the functions: 'Zero', 'Micro', 'Home', 'Set', 'Start', 'Stop'.

5. Enter the parameter setting interface by clicking 'Set' and configure the test times and speed (timer and counter mode are available for selection).

6. Prepare the samples and necessary testing tools (Allen wrench, chisel cutter).

7. Open the safety cover, which disengages from the limit switch.

8. Adjust the fixture rotation shaft to its lowest position for sample installation. If it's not already in the lowest position, use the controller button for adjustment.

9. Use the Allen wrench to unscrew the upper fixture. Secure the test sample in place and tighten the screws. The machine can simultaneously test six samples.

10. Activate the jog button to move the sample to its highest position.

11. Employ a chisel cutter to create an opening on the sole at the center of the shaft. Measure the width of the notch using a caliper and record the measurement.

12. Reset the current data and set the number of tests. Then initiate the testing process.

13. The machine will automatically halt once it completes the predetermined number of tests.

14. Open the cover and utilize the jog button to position the fixture at its highest point. Reassess the notch width. (Compare the width before and after the test to ascertain its qualification)

15. Remove the sample after testing.

IV. Maintenance and Cleaning

To ensure the long-term stability and testing accuracy of the Whole Shoe Sole Flexing Tester, maintenance and cleaning are paramount. Maintenance entails regular checks of equipment components to ensure integrity and prompt repairs or replacements when necessary. Cleaning involves surface cleansing of the equipment and proper handling of tested samples to maintain cleanliness and accuracy for subsequent tests.

Equipment Maintenance: Regular maintenance not only prolongs the device's lifespan but also enhances the reliability of test results. Periodic inspections of the mechanical structure, electronic components, and connections facilitate timely detection and resolution of potential issues, preventing malfunctions or performance degradation. Additionally, regular lubrication of moving parts minimizes friction and wear, ensuring smooth operation.

Routine Cleaning: Cleansing the surface of the SATRA TM161 Sole Flexing Testing Machine eliminates dust, dirt, and other debris, preserving its appearance and mitigating the impact of pollution on test results. Similarly, handling tested samples appropriately—such as storage, recording, or further analysis based on test results and requirements—assists users in comprehending test data and making informed decisions.

Conclusion

By adhering to the correct operational procedures, users can guarantee the accuracy and reliability of ISO20344 Soles Flexing test results. Proper operation not only boosts testing efficiency but also safeguards the credibility of results, providing essential groundwork for product quality control and enhancement.